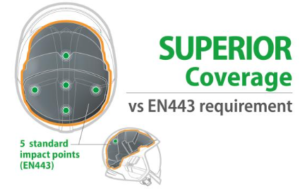

MSA never compromises on the safety of wearers. Each component is evaluated and tested using a clear protocol. Because the material itself is not everything, MSA has also chosen not to restrict itself to what is described in the EN443 standard (Helmets for firefighting in buildings and other structures) to ensure maximum security for wearers, especially with regard to the safety critical components of the helmet.

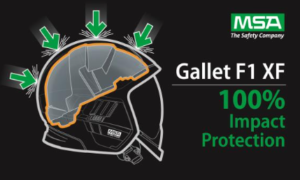

Better impact protection with high coverage liner

Better impact protection with high coverage linerThe size of the GalletF1 XF impact liner has been wearer against shock and heat, and not only up to half of the skull. Because of shock to the forehead could be fatal.

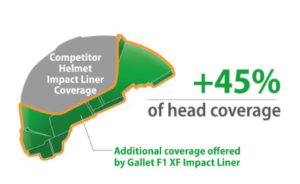

Tests conducted internally in our laboratory on several EN443-certified helmets prove that impact to the shell alone, in an area not protected by the impact liner, can seriously injure the wearer. So MSA decided to go beyond the normative requirements, and opted for maximum protection rather than limiting itself to the minimum size needed to meet the standard.

The Gallet F1 XF impact liner consists of shock absorbing high density polyurethane foam with over moulded aramid reinforcement. It provides full protection (impact and penetration) for the top, front & sides of the helmet–not only for the 5 impact points listed in EN443. As a result, the Gallet F1 XF impact liner covers almost all wearer’s head. There is no compromise to safety.

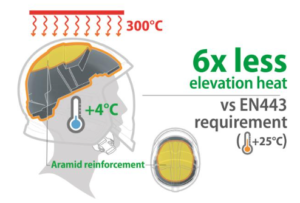

The aramid layer on the top of the impact liner also provides a higher thermal performance. The thermal protection it delivers proves to be a major competitive advantage too, as it is perceivable by users in hot trainings or real fire situations. In many real fire testing situations, it succeeded in negating any heat breakthrough longer than any other helmet.

The Radiant Heat exposure test (EN443:2008 section 4.7) aims at submitting 14kW/m² heat flux (approx. 300°C) for 8 minon one of the side impact point (left orright). It is then controlled that the temperature measured on the head form does not increase by more than 25°C. After exposure, and within 60 seconds, an impact test (shock or penetration) is performed to check the helmet’s mechanical performances when exposed to extreme heat stress. The average temperature increase under a Gallet F1XF is only around +4°C(average based on 205 lab tests recorded on the Gallet F1 XF), and the force transmitted to the head form is way below the limit of 15kN, with fully maintained protection against penetration.