For many fire departments, garment cleaning and maintenance already has an established protocol, with many brigades working with PPE suppliers. However, there has been a strong culture that says, “The dirtier the kit the more of a hero the firefighter!”. There’s a growing realisation that actually, the dirtier the kit, the greater the risk of exposure to harm. In some regions, the culture is changing with firefighters having a better understanding of the risk and demanding a clear set of guidelines to help them safely wear, remove and decontaminate or clean their kit.

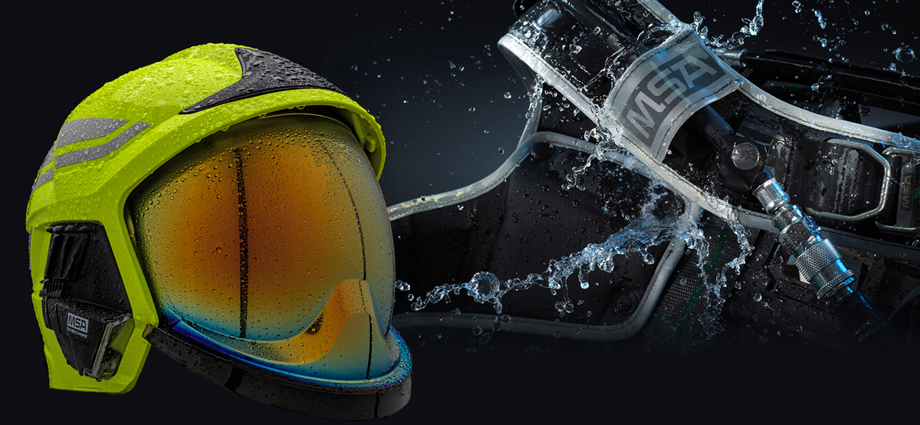

MSA is working with its customers to provide a “head to toe” recommendation on cleaning and disinfection of its flagship products, such as SCBA and Fire Helmets. As a trusted advisor to brigades all over the world, MSA has established a set of recommended guidelines on cleaning and disinfection available in the product manuals.

Cleanability is now one a key focus for all new product development. MSA is helping to advise its customers of industry-accepted cleaning and disinfecting processes and procedures in an effort to help maintain firefighters’ equipment and protect it from damage caused by cleaning agents or the cleaning methods themselves.

Talking to our customers, we’ve learned that, not surprisingly, equipment cleaning is their number 1 concern. As well as wanting to bring the most innovative equipment on the market, MSA considers various aspects of a fire fighter’s working environment and designs a product that can be easily cleaned and disinfected (for example relying more on self-repelling textiles).

The MSA M1 SCBA has been designed with this in mind. All of the backplate narrow spaces and angles are easily reached, the harness is made from dust and water repellent materials that reduces time for mechanical cleaning, aids fast drying and is tear resistant, making it suitable for repeated mechanical wash.

The kit is easy to disassemble and maintain. For example, the G1 mask can be disassembled in less than 30 seconds – and the entire SCBA can be machine washed with no disassembly required.

For light soiling the entire SCBA, hoses, pressure reducer and pressure gauge cleaning can be carried by hand with a brush or damp cloth or underwater, ensuring the correct steps are taken to avoid water ingress or penetration.

Machines can be used to clean complete and pressurised SCBA. Rough dirt should be removed with a water hose before the equipment goes into the machine.

After heavy soiling, the M1 SCBA can be cleaned first with a hand pre-wash, followed by machine cleaning, following the same protocols as machine cleaning.

All components of any SCBA that have come into contact with the saliva or the exhaled breath of the user must be disinfected such as full face masks or lung- governed demand valves (LGDV). As opposed to general cleaning, disinfection destroys micro-organisms such as bacteria and fungi. Only clean breathing apparatus components can be disinfected so users should follow the hand and machine cleaning protocols first, before disinfection takes place.

It is critical to make sure that the pressure reducer is dry before it is returned to service to avoid the potential risk of icing. You may use an air gun to dry the pressure reducer (provided that it is compressed air with breathing air quality according to EN 12021).

As a leading safety products manufacturer, MSA is focused on continuing to innovate on behalf of firefighters around the world so that their personal protective equipment will work together to help keep them safer than ever before. With heightened awareness of the inherent risks they are facing, MSA is actively working with its customers to provide guidance by communicating industry accepted best practices on the total care of equipment.